Technical Glossary

Anodic Oxide Coating or Alumite Treatment

Anodic Oxide Coating, also called Alumite Treatment, is a surface treatment in which an oxide film is formed by the electrolytic treatment of aluminum with an anode (positive pole). Alumite is a registered trademark of RIKEN. However, it is now a generic term for oxide films formed by anodic oxidation treatment.Aluminum is a non-ferrous metal that naturally joins with oxygen displaying a thin oxide film. Accordingly, it can also be used without anodic oxide coating. However, it may corrode depending on the environment. Therefore, we perform anodic oxide coating as necessary. We use this for the surface treatment of the clamp hubs, including SERVOFLEX Couplings / SFC Models.

In contrast to performing anodic oxide coating by electrolytic treatment with an anode, performing it with a cathode is called plating treatment. Moreover, the film develops up and down within the anodic oxide coating. Therefore, if the surface of the aluminum is rough, the finish will also be intimidating because it will be subject to surface treatment as it is. Furthermore, when performing multiple anodic oxide coatings, the surface thickness will be reduced due to the coating being removed. In contrast to this, plating treatment is added to increase viscosity.

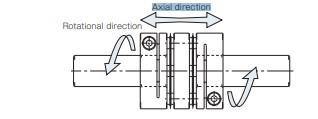

Axial Direction

Axial Direction refers to the "parallel direction" concerning the center of the axis on which a coupling is mounted. Miki Pulley calls bolts mounted in the parallel direction for the center of the axis among bolts that fix in place rubber bodies and elements in CENTAFLEX Couplings "A direction bolts" ("A" stands for axial).

We distinguish the term that indicates the parallel direction concerning the center of the axis in the same way for the allowable error as a term for couplings in general by calling it the "axial direction" (sometimes also called the thrust direction).

Please Note: Radial direction (vertical direction) corresponds to the axial direction (parallel direction).

Backlash

Backlash refers to mechanical rattling at the points where there is no transmission, even if there is rotation when gears are engaged. Backlash is not appropriate for machines that require high positioning accuracy.

"Completely no backlash" is given as one of the strong points of the SERVOFLEX Couplings in the catalogs of Miki Pulley. In other words, no backlash means that there is no mechanical rattling. Therefore, they are suitable for the high-speed and high-precision positioning of servo motors and ultra-precision control applications.

We provide "feature icons" that indicate the function and performance on the coupling production lineup page in catalogs, so please refer to this when making your selection.

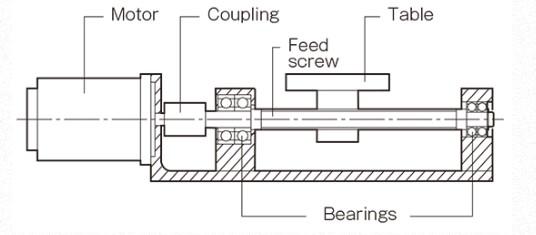

Ball Screw

A Ball Screw refers to "feed screws" in which a ball "rolls" between the valley of the male thread and female screw threads.

The rolling motion reduces frictional resistance, providing a simple way to obtain high efficiency.

Ball screws consist of screw axes, nuts, and bolts. However, bolt screws alone cannot transmit power. Accordingly, it is possible to convey the rolling motion of motors into linear motion by linking them to motors with couplings. Consequently, ball screws are widely used in the transferring and positioning semiconductor manufacturing devices, industrial robots, and machine tools.

Black Oxide Coating

Black Oxide Coatings is a surface treatment used to prevent rust by forming an oxide film on the surface of iron and steel. It is called black oxide coating because the finish is a glossy black. It is called "iron tetroxide coating" because it forms an oxide coating.

Anti-rust oil should be used to protect a metal’s surface if it is not used or is being stored for an extended amount of time.

Black oxide coatings are used in the hub surface treatment of Miki Pulley SERVOFLEX Coupling / SFS Model and SERVORIGID Couplings. The advantage of a black oxide coating is that it is performed with a chemical reaction. Therefore, it does not peel off like plating processing and painting processing treatments. Furthermore, the layer is thin (differs depending on the treatment time), so there is almost no impact on the dimensional accuracy.

Please note: There is a danger of rust forming if a metal is stored for an extended time after purchase.

CENTAFLEX

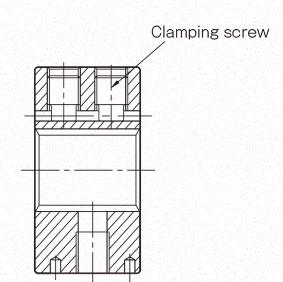

A CENTAFLEX provides a unique method to completely fix in-place spline axes and couplings (cylindrical hubs) within Miki Pulley’s CENTAFLEX Couplings. CENTAFLEX sets in place with the addition of a force around the spline processing part by tightening the clamping screw.

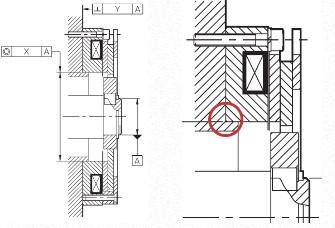

Centering Location / Spigot Joint

The Centering Location or Spigot Joint is an assembly method that uses convex and concave parts to facilitate alignment by aligning convex areas processed on one piece and concave regions on the other when fastening by aligning the center of parts.

The container and lid of the spigot joint are made to fit perfectly. Alignment in which parts fit together perfectly like this is called the centering location or spigot join due to this spigot structure.

We ask that you employ a mounting method with the centering location/spigot joint to ensure that the centering of the two axes in Couplings and the fixing in place of the mounting surface and axis of brakes within Miki Pulley Electromagnetic Clutches and Brakes, ensuring advanced performance.

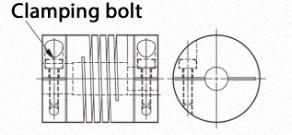

Clamping Bolts

Hubs and axes are fixed in place by tightening clamping bolts and narrowing the slits processed onto the clamping hubs.

It is possible to securely fix in place hubs and axes by tightening with the appropriate "tightening torque" for clamping bolts.

Clamping Hub

⇒Please also read the "clamping screw" term.

⇒Please also read the "center lock" term.

Clamping Hubs refer to a hub fixed in place with spline axes using the function of center locks. We call the cylindrical hubs used clamping screws in CENTAFLEX Couplings "clamping hubs."

A clamping hub is a general term for hubs with slits in SERVOFLEX Couplings, STEPFLEX Couplings, and STARFLEX Couplings.

In addition, the bolts used in clamping hubs are called clamp bolts.

*HELI-CAL Couplings are integrated parts, so they do not have hubs. However, the method of fixing in place with an axis with a clamping bolt has the same structure.

* CENTAFLEX Couplings have a clamping hub and clamping screw. The concept of fixing in place the hub and axis is the same. Nevertheless, the names are differentiated because the structures are different.

Clamping Screws

⇒Please also read the "clamping hub" term.

⇒Please also read the "center lock" term.

Clamping Screws utilize a unique shape inserted into threaded screw holes processed into clamping hubs to fix in place clamping hubs and spline axes by using a center lock in CENTAFLEX Couplings. *Similarly, there are also clamp bolts to fix place hubs and axes. However, these are used in clamping hubs with slits (e.g. the SERVOFLEX / SFC Model).

Clockwise

Clockwise travels in the same direction as the hands of a clock.

*The opposite is counterclockwise (CCW).

Computer Numerical Control Lathe

⇒Please also read the "Numerical control lathe" term.

NC stands for numerical control, while CNC stands for computer numerical control.

Counterclockwise

Counterclockwise travels in the opposite direction the hands of a clock travel.

*The opposite is clockwise (CW)

Coupling

Couplings are articles that connect axes. They play a role in transmitting the power of machines to the other side. Most of the couplings handled by Miki Pulley are called flexible couplings. Couplings can transmit rotations and energy even if the centers of the axes are misaligned.

Conversely, there are also highly rigid couplings with no such flexibility. These are handled under the name SERVORIGID Couplings" by Miki Pulley.

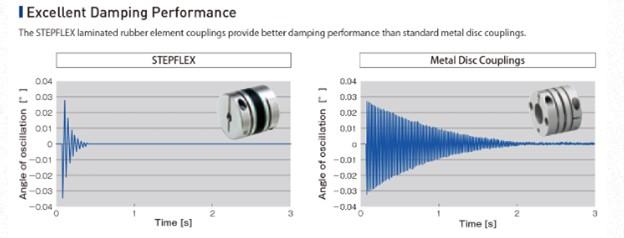

Damping Performance

Attenuation is a vibration phenomenon in which amplitude gradually decreases over time. The shorter this time, the higher the attenuation performance. The "high attenuation performance" that is one of the strong points of the STEPFLEX Couplings of Miki Pulley comes because they quickly absorb the vibrations. This is because the elastic part (element) material of the couplings is rubber.

Flexible couplings made with metal for the elastic part are hard in the torsion direction. This means they excel in rotation transmission. However, rubber has better vibration absorption. Consequently, please select the best coupling to suit the precision, performance, and use of the machine you require.

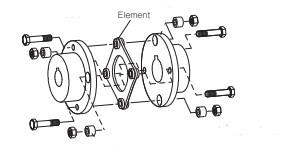

Elements

These are important parts that transmit power in couplings, often referred to as elements. The materials of elements are metals, resins, and rubber. They are parts that have the most impact on the performance of couplings (especially the torsional spring constant and mounting error). They are sometimes called "cushioning" in Japanese.

In addition, we use different terms for the "spiders" of SPRFLEX Couplings and the "metal coil springs" of BAUMANNFLEX Couplings. However, the functions of these are equivalent to elements.

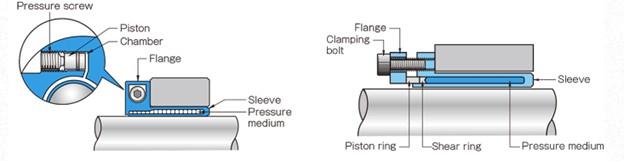

ETP Bush

⇒Please also read the "Pascal's principle" term.

This refers to a friction fastener that fastens the axes and hubs handled by Miki Pulley with the pressurization of a pressure medium. Simply put, an ETP Bush inserted between an axis and hub is a product that expands to fix in place the axis and hub. One of the most unique aspects of the ETP Bushes developed by ETP in Sweden is that it can be called a pressure medium. The pressure medium expands the ETP Bush and is enclosed in the ETP Bush body. Similarly, it has a structure in which the pressure medium is pressurized, and the sleeve of the main body expands by tightening a pressure screw or clamping bolt of the body. Although we say expand, it does not deform to the extent that is visible.

Fastening with a key and keyway that fixes in place an axis and hub is the most typical means of fastening. However, keyway processing on both the axis and hub is necessary for this. Furthermore, the work to insert a hub that has been subject to keyway processing into an axis with a key mounted is very difficult. Therefore, we believe everyone will have experienced the frustration of it biting halfway through without it going smoothly at least once. Insertion is easy with an ETP Bush. Furthermore, the mounting time is just 20 seconds for models that fasten with one bolt. There is even no time to get frustrated.

When we first launched ETP Bushes, we were faced with the doubt of whether there would be slippage by fixing in place with friction force. There is complete peace of mind with key fastening. Nevertheless, if that is the case, the tires of cars and bicycles also cannot be believed. That is because they stop due to friction force. Of course, key fastening has been adopted for many years. Therefore, it is possible to reduce processing costs with keyway processing facilities and there is no problem with key fastening if there is nothing when used.

However, the most unfortunate thing about key fastening is the large rattling that occurs while being used rather than the frustrating mounting. In other words, backlash occurs. There are no keyways on servo motor axes. You probably already know the reason for that. That is because the backlash of key fastening is the great enemy for the high precision movement of servo motors. ETP Bush friction fasteners combine both workability and high precision in the fastening of axes and hubs in this way.

Export Administration Regulations

⇒Please also read the "parameter sheet" term.

EAR refers to the "Export Administration Regulations" in U.S. law. Products and technologies that contain parts originating in the U.S. are subject to these regulations. If they do not contain such parts, they are not subject to the regulations. Accordingly, these regulations are involved in trade around the world. For example, when exporting from Japan to China, products that contain parts originating in the U.S. are subject to the EAR. In other words, even if the U.S. is not the country to which products are being exported, it is necessary to consider the EAR decision.

In this way, products and technologies that contain parts originating in the U.S. are subject to the "re-export regulations" in the EAR when being exported from Japan to other countries. *The fact there are parts originating in the U.S. in Japan means that they were first exported from the U.S. to Japan. When these are exported from Japan to another country, it means that they are being exported again. Therefore, we call this "re-exporting."

Flange

This refers to the part that juts out in a brim shape from products like parts with a large flange hub diameter. Alternatively, the parts with such a shape may themselves also be called flanges.

Flange Hub

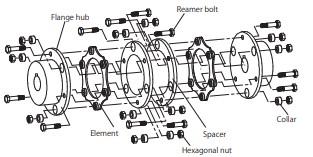

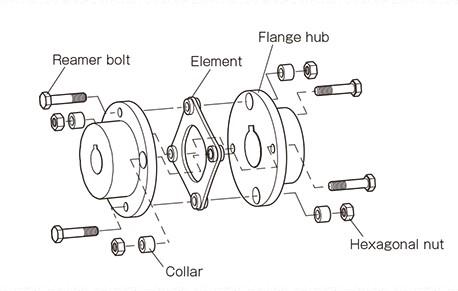

This is one of the hubs for fixing in place the rubber bodies and elements in CENTAFLEX Couplings. The bolts to fix in place the rubber bodies or elements to the flange hub are mounted parallel to the center of the axis onto which the coupling is mounted. Therefore, they are referred to as "A direction bolts" (A is the abbreviation for axial). *There are cylindrical hubs as hubs used as a pair with flange hubs.

Flywheel

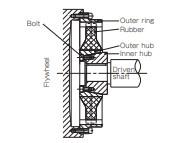

⇒Please also read the "CENTAFLEX" term.

This refers to a disk that stabilizes rotation. Even if the reciprocating motion of a piston generated with an explosion like an engine is transmitted to the rotational movement of a crankshaft without change, the rotation will not be smooth. Accordingly, it is possible to stabilize the rotation with inertia by mounting a flywheel to it.

However, if there is insufficient stabilization with just a flywheel, it is possible to obtain extremely stable rotation by directly mounting a CENTAFLEX Coupling to the flywheel and linking it to the shaft because the CENTAFLEX will absorb the vibrations. In this way, the CENTAFLEX is widely used in mechanisms in which engines of construction machinery (e.g., excavators) or ships and engines connected to propellers serve as the drive source.

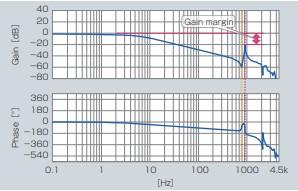

Gain

This is the ratio of output with respect to the input of voltage, current and power in control systems. The unit is decibels. This is called gain. Alternatively, it can also be called the amplification rate because the input is multiple times the size of the output.

It is often possible to hear the phrases "high gain" and "gain adjustment" in motors that rotate at high speed with high precisions like servo motors. In other words, increasing the gain means increasing the output so that it is possible to operate at even high precision and speed. Servo motors now adjust to the optimal gain with auto tuning. However, if the gain is too high, it will go past the target position. Furthermore, it will attempt to return to the target position after going past it. That movement becomes vibrations. This means it is necessary to adjust the gain manually. Gain adjustment includes "position control," "speed control" and "torque control." It is possible to achieve the best high precision and high speed rotation by adjusting to the optimal gain with a combination of these.

The STEPFLEX Couplings of Miki Pulley quickly attenuate the vibrations generated at that time even if set to high gain. Accordingly, it is possible to achieve stable high-speed control.

Gantry

A gantry is a moveable structure that has the shape of a gate. Accordingly, the gantry mechanism is referred to as a mechanism in which gate-shaped parts straddling two parallel orbits move. You can think of this as being like a pedestrian bridge moving in line with a sidewalk.

SERVOFLEX Couplings are suitable for gantry mechanisms because couplings with high torsional rigidity are required to simultaneously operate and smoothly move two orbits. It is often possible to see gantry cranes in gantry mechanisms. These are cranes that load and unload while moving the cargo of a container ship in a port on a rail.

Hammering

This refers to the adjustment of an object with light tapping by a tool hammer. We give an explanation so that you can adjust the flange outer circumference and edge with hammering as a means of centering for the SERVOFLEX Coupling / SFF Model.

Hexagon Head Bolt

⇒Please also see our "Hexagon Head Bolt Shapes and Dimensions" technical document.

This is the general term for bolts with hexagonal heads. We use spanner-shaped heads that fit hexagon heads when tightening bolts. Hexagon head bolts are used in various ways in the products of Miki Pulley. For example, we have available a type that uses hexagon head bolts in clamping bolts in our Mechanical Axis Lock / POSILOCK products. In addition, hexagon head bolts are used as pressure bolts in the friction fastener hubs of our SERVOFLEX Couplings.

"Hexagon socket head cap screws" are often used together with hexagon head bolts. However, here, we use hexagon heads (hexagon wrenches) when tightening bolts. To that end, it is necessary for hexagon socket head screws to have a much wider space to be able to tighten. If it is difficult to obtain such a space, it would be best to select the hexagon head bolt type.

Hexagon Socket Head Cap Screw

⇒Please also see the "Hexagon Socket Head Cap Screw Shape and Dimension Standards List" technical document.

This refers to hex socket head cap bolts. We use hexagonal wrench-shaped hexagon heads that fit hexagonal holes when tightening bolts.

Hexagon socket head cap screws are the part used the most commonly in the products of Miki Pulley. They are used with the name of clamp bolts or A and R direction bolts in various couplings. In addition, we believe they are often used when fixing the products of Miki Pulley to the bases of the machines of our customers.

We also tighten hexagon socket head screws with a torque wrench or torque driver. Furthermore, it is necessary to manage the tightening torque suitable for the strength classification of the screw. If the screws are not tightened at the appropriate tightening torque, they may become loose. Please take care because this may occur regardless of whether they are tightened above or below the appropriate tightening torque. Moreover, Miki Pulley performs special surface treatment and looseness prevention on screws depending on the product for the hexagon socket head cap screws of our couplings. Therefore, please take care when handling them.

You may have realized that we refer to these as bolts in Japanese but screws in English. "Hexagon head bolts" are bolts. In fact, we call everything bolts in Japanese, However, there is a difference between bolts and screws due to their different usage methods in English.

That is because hexagon head bolts are generally used together with nuts. Accordingly, bolts are used together with nuts and those that are not screws. The typical usage method of these is reamer bolts in our SERVOFLEX Couplings / SFS Model. Here, the customer fixes in place reamer bolts with nuts.

HS Code

This refers to the code established under the HS Convention given to all items subject to trade. The HS Convention is an international treaty on the Harmonized Commodity Description and Coding System. It is managed by the World Customs Organization (WCO).

When declaring imports and exports to customs in Japan, we enter a nine-digit number corresponding to the cargo we are declaring. This number is called the "harmonized system code." The first six digits of this number are the HS code. Items are classified by the same rules in countries around the world. Therefore, the same number indicates the same item.

The reason why the harmonized system code or HS code are necessary is to find out the tariff rate. Tariffs vary by country. However, the numbers are shared. This means that is possible to know the tariffs of the other country even without knowing the language of that country.

For example, the HS code of Couplings is "8483.60," (The harmonized system code is "8483.60 000".) It is possible to check the harmonized system code on the customs website. If we search for "couplers" from "trade harmonized system" → "export harmonized system item list" → "class 84: reactors, boilers, and equipment and parts equivalent to these" → "item list → list, we can learn the harmonized system number and HS code. There is "clutches and couplers (including universal joints)" in the "8483.60" HS code. Nevertheless, let's check an even more detailed explanation just in case.

Let's look at class 84 in "trade harmonized system" → "tariff rate list explanation / classification rules." "Sleeve joints, flange joints, flexible joints, fluid joints and universal joints (those like hook joints and Oldham joints) included here" is found in the item described for "8483.60." Accordingly, we can verify that this is the HS code for the couplings handled by Miki Pulley.

Idler

When power is transmitted by a belt and chain, the belt and chain stretch a little while they are being used. This becomes slackness and then generates vibrations and noise. This has an impact on the power transmission.

Accordingly, products which eliminate slackness caused by this stretching are called tensioners. The part which is mounted to this tensioner to come into contact with the belt and chain is called an idler.

Miki Pulley also handles products with the function of a tensioner. One of these is our ROSTA Tensioner. We have available a RSE model that comes with a "roller idler" and a NSE model that comes with a "sprocket idler."

In addition, we have a model that comes with a "tension pulley" (the black part in the figure on the right) with the same function as an idler for our L model of Belt Type Stepless Speed Changer Standalone Items.

International Energy-Efficiency Class Code

⇒Please also read the 「"motor"」 term.

⇒Please also see the 「"Premium Efficiency Motor Specifications List"」 technical document.

This refers to the three-phase motor efficiency class. IE3 motors are premium efficiency motors.

Inverter

Inverters are devices that control the rotational speed of motors to a stepless speed by freely setting the frequency and voltage of the AC power supplied to the motor. Originally, power conversion devices that alternate direct current are called inverters and devices that convert AC to DC are called converters. Devices that make it possible to control motors by setting this to a circuit in which it is possible to freely set the frequency or voltage have now become known as inverters.

When there was no inverter, the rotational speed of the motor was constant, so the rotational speed was changed with a Belt Type Stepless Speed Changer of Miki Pulley. Furthermore, there are regions with 50 Hz and 60 Hz in Japan and various power situations around the world. Therefore, schemes in themselves are necessary to obtain a rotational speed that suits your situation.

Accordingly, with the advent of inverters, it is possible to freely set the rotational speed of motors. Therefore, it has become possible to combine increasing the speed of one task while decreasing the speed of another task. Furthermore, this has also been adopted in products using various motors in addition to industrial machinery. "Inverter air conditioners" and other products have been launched. Inverters have also evolved up to now. Therefore, the standard specifications consider the environment in terms of also contributing to energy saving and a reduction in CO2. This is in addition to the advantages of inverters of making it possible to obtain a high motor efficiency and having few rotational vibrations even at low speeds.

The Inverters of Miki Pulley come with functions optimal for a variety of small capacity needs with our unique design concept cultivated over many years of experience. It is possible to set the output frequency up to 400 Hz. Furthermore, an automatic energy