Spider Couplings

Spider jaw couplings are designed and manufactured with protruding lugs on each hub, centrally connected by an elastomer “spider” insert between the hubs. The aluminum construction minimizes the moment of inertia. The spider jaw type coupling’s shape and material reduce reaction loads resulting from misalignment. The non-conductive elastomer also provides electric isolation between both shafts.

Contact us for more information on premium Jaw & Spider Couplings for general-purpose motor connections, servo motor applications, and more. Browse our catalog for more product listings. Miki Pulley is your trusted manufacturer of flexible jaw & spider coupling components and accessories.

Precision Manufactured Spider Jaw Couplings from Miki Pulley

Miki Pulley Jaw and Spider couplings are meticulously crafted from premium materials, ensuring durability and reliability even in demanding applications. Our innovative couplings allow for high torque transmission and exceptional misalignment compensation, reducing wear and tear on connected components and minimizing maintenance costs.Miki Pulley Jaw and Spider couplings deliver unparalleled value, delivering premium, long-lasting coupling solutions for industrial applications at competitive prices. Miki Pulley is your solution for the best jaw and spider couplings on the market.

Spider Jaw Coupling Advantages

Miki Pulley jaw couplings accept shaft misalignment, offering high load capacity while maintaining a damping effect on vibration and thermal conductivity. Each of our flexible spider jaw coupling models offers different torque ratings and performance levels determined by the durometer of the elastomer spider, delivering unprecedented adaptability for everything from general-purpose motor connections to demanding servo motor applications.- Fail-safe design and long service life

- Transmits up to 387 ft-lbs. (525 Nm) of torque

- Low reaction loads

- Low to zero backlash, depending on the model

- High torque capacity and torsional stiffness

- Quiet operation

- Easy to install

Curved Jaw Coupling Product Options

Miki Pulley offers high-quality elastomer jaw-type couplings with a pilot bore (minimum bore) or a bored-to-size option. Select from four spider element durometers based on your misalignment capacity and performance requirements. All the elastomers used in our couplings provide good resistance to oils and chemicals. ALS-R Jaw-Type Couplings

The ALS-R curved hub shaft jaw coupling features a Curved-Jaw profile design, offering a slight pre-compression of the spider and Type “R” elastomer spider element while providing 97 shore hardness. This hub jaw coupling model offers high torque, high torsional stiffness, and zero backlash, with a limited capacity for shaft misalignment.ALS-Y Jaw-Type Couplings

The ALS-Y hub jaw coupling features a Curved-Jaw profile, offering a slight pre-compression of the spider and Type “Y” elastomer spider element while providing 90 shore hardness. This model offers a good balance of performance and flexibility for shaft misalignment. The tightly fit spider element creates a zero-backlash connection and has a moderate level of torsional stiffness for system responsiveness.ALS -B Jaw-Type Couplings

The ALS-B hub split spider shaft coupling features a straight jaw profile and Type “B” elastomer spider element while providing 97 shore hardness. This model offers a looser fit for handling more significant amounts of shaft misalignment with minimal backlash while delivering a high torque capacity.AL SPRFLEX Jaw-Type Couplings

Spider Jaw Coupling Hub Shaft Connection Options

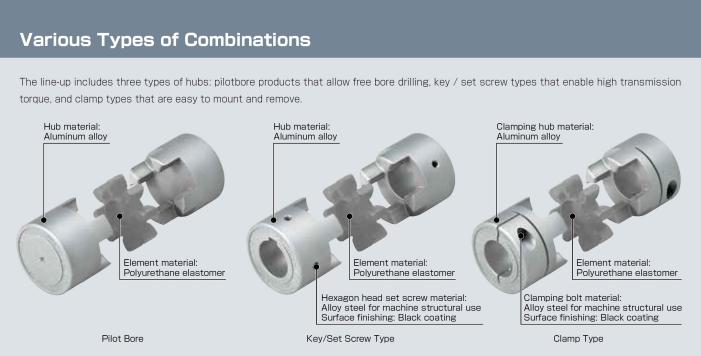

ALS-R, ALS-Y, and ALS-B elastomer jaw-type couplings models have a clamping or set-screw/keyway hub. Our AL SprFlex couplings have a pilot bore, set-screw/keyway hub, or clamp hub.- Pilot Bore: Less costly option allows the customer or end-user to machine the bore to their specifications.

- Key/Set Screw Style: Enables a simple shaft connection, allowing for high torque transmission.

- Clamp Style: Designed for easy mounting and removal, it provides a secure shaft connection. It is typically keyless; however, keyways are available upon request.

Contact Miki Pulley for Jaw & Spider Couplings Today

Miki Pulley offers near-zero backlash jaw and spider couplings, providing a failsafe design and long service life to meet your project needs. Custom configurations are also available. Contact us at 800-533-1731 to discuss your application or request a quote today.